- Category

Shop By

Shopping Options

-

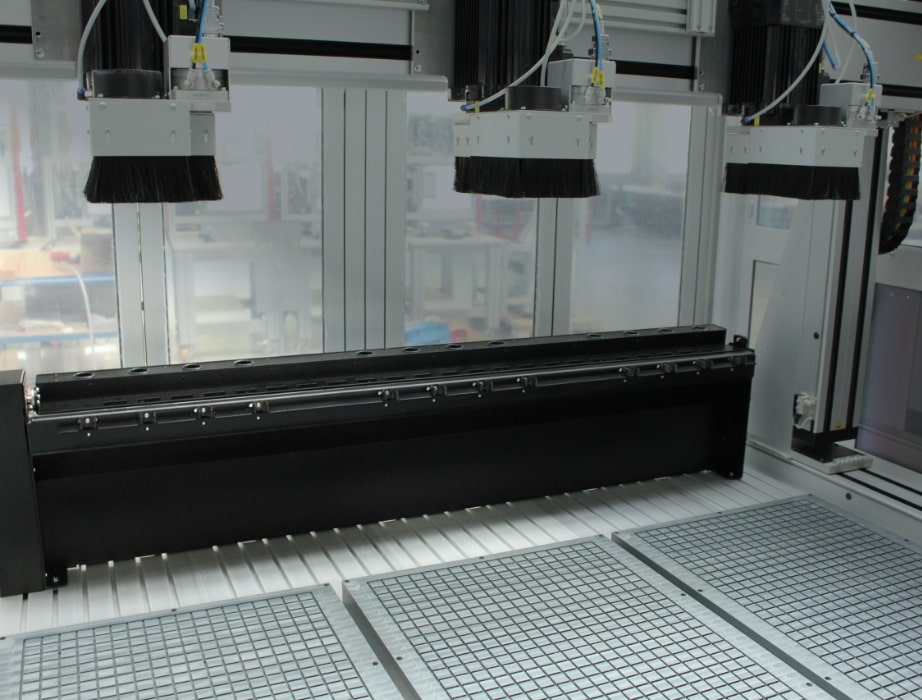

More InformationCNC machines for applications of all kinds

The CNC milling machines by isel are specially designed for your application. The machines meet high requirements and the high level of precision

- suitable for multi-shift operation

- Configurability of any linear and rotary axes

- Large travel distances with small dimensions

- Windows-based control with open interfaces

- Option of the direct integration into automated processes

From the craftsmanship to the industrial manufacturing CNC machines with performance and precision

CNC machines from isel are well thought-out solutions for a wide variety of applications. In smaller craft businesses, the said machines are just as indispensable as in the industrial manufacturing. The company isel germany develops high-performance CNC machines for you which are individually adapted to your requirements, from the milling machines to special machines.

Special machines

Ideal adaptation to your requirements

The perfectly suitable CNC machine by isel

Profit from our personal advice and trust the efficient, powerful, and highly precise CNC machines manufactured by isel.

Schedule a consultation nowWe are the specialist at your sideOver 50 years of experience on the market

Sophisticated and advanced CNC machines: as a german manufacturer and expert, we know what really matters. This is the exact reason why we have had over 1,000 satisfied customers in more than 40 years. Whether for medical technology, automotive industry, optics, dosing technology, orthopaedics technology, metal, plastic or wood processing - we have the perfect CNC machine which is suitable for you.

Customized solutions and systems

With our customer-specific solutions and systems, you receive the CNC machines which are optimally adapted to your requirements. In the course of the decision-making and implementation phase, the focus will be on individual advice. After that, we support you worldwide with extensive training offers and our fast and professionally competent support. With isel germany as your partner, you will get everything from a single source - made in germany.

Reliable maintenance and fast repair

Manufacturing downtimes result in high costs! Thanks to our attractive maintenance offer, adapted to diversified manufacturing conditions, you will be able to minimize this risk. However, a fault can never be avoided 100%. In this case, our experienced service technicians will be on site within a short time. As an alternative, you can get a quick and reliable solution to the problem through the remote maintenance function of your CNC machines.

Personal and direct service

For isel Germany, personal service has high priority. As a reliable partner, we are there for you whenever you need us. This applies to general questions about our products, to the development of individual solutions, to training courses tailored to your requirements or services on your CNC machines. We accompany you through your CNC machine project from the first consultation to regular maintenance or quick repair.

Come and see for yourself!

For more than 50 years, we have been developing efficient and innovative full-service CNC solutions for our customers. Whatever application you are looking for a CNC machining centre for, we will supply the perfect system. In the course of the past decades, we have been able to convince large and internationally active companies to put their trust in our CNC machines. Small and medium-sized businesses also benefit from this. Since our smart and powerful solutions adapt to your requirements.

Your questions and our specialists answerCNC machines of the highest quality

Get answers to your questions here. Browse our extensive FAQ or contact us directly – our team is ready to provide you with answers and solutions.

What does CNC mean?

CNC is the abbreviation "computerized numerical control". The CNC process is a computer-aided manufacturing process for multi-dimensional machines, the so-called CNC machines.

Where are CNC machines used?

The CNC machines are used in a wide variety of areas. In craft as well as in the industrial manufacturing process. Depending on the design and tool, they are suitable for milling, turning, cutting (with water jet), drilling, engraving and other work. With these machines, plastics can be processed just as successfully as metal.

What is the difference between CNC and NCmachines?

NC is the abbreviation of "numerical control". They are the predecessors of the CNC machine and are hardly in use anymore due to the outdated technology. In nc machines, the data for machining a workpiece is stored on punch cards which are placed in a punch card reader and read out. Nc machines are not very flexible as soon as the processing process begins after the data has been read in. With CNC machines, you can still make minor changes as well as optimizations in the course of the machining process.

What are CNC machines?

The CNC machines are powerful machines. Modern machines are controlled through an integrated microcomputer, on which the required control programs are created directly through a cad/cam system.

What are the crucial aspects when purchasing a CNC machine?

A CNC machine must be optimally adapted to the requirements of a manufacturing process of the company. This principle applies to the processed material, the dimensions of the workpieces and the functionalities. Equally important is the high quality of the various components, as they are exposed to high loads during the operation. The software should be easily understandable and intuitive to use in order to optimize the training effort. As an alternative, the manufacturer should provide an all-comprehensive training programme. Another essential aspect is the compatibility with various cad software solutions.

How many axes do a CNC machine have?

Depending on the design, a CNC machine has between two to six machining axes. The basic axes are the y and x axes. The third axis is the z axis, which often runs in parallel to the work spindle. These axes are movement axes representing the main axes. The remaining three axes are auxiliary axes serving as rotary axes. The more complex a workpiece is, the more axes will be required. For this reason, the number of axes is always based on the individual area of application.

What are the advantages of CNC?

The advantages offered by the computer-controlled technology are the high efficiency of manufacturing, but also the high and reproducible precision with which the workpieces are processed.

What are the advantages offered by the CNC machines?

The CNC machines work multi-dimensionally over two to six machining axes by carrying out all the work steps required on a workpiece in one operation. Even highly complex geometries can be implemented without any problems. As a result, a high time saving will be achieved in the manufacturing process. Thanks to the computer-controlled technology, the CNC machines will achieve very high and repeatable precision at all times. Particularly powerful machines even carry out the tool change in an automatic manner and even monitor tool wear or breakage. As a result, the support provided by auxiliary personnel will be additionally reduced. Another advantage is the high degree of individualization. In this manner, the machines can be individually adapted to the manufacturing requirements. There are simple CNC machines which are suitable for a machining process such as milling or turning, but also so-called CNC machining centres in which a workpiece goes through several machining processes.

What is the average machine throughput of CNC machines?

Additional information will be required to answer this question. Indeed, the machine throughput depends on various factors such as the type of drives or the area of application. Consequently, the spindle motors travel about 0.2 mm per second, while linear motors reach between 2 and 3 mm per second.

How do CNC machines work?

The CNC machines are computer controlled and receive their commands to move the different machining axes through a program. This is created in a cad software and converted into a CNC program by a cam software. This situation creates understandable and correctly executable instructions for the machine. The basis consists of a three-dimensional coordinate field within which the tools move according to the control instruction.

How are CNC machines powered?

The drive systems of a CNC machine are equipped with ball screw or linear drives. Both drives have hardly any play, which ensures a high precision level during the machining. The gantry drive is often used in portal milling machines. In this type of drive, two separate feed motors operated in an angle-synchronous manner move a common drive axis.

What are the components of a CNC machine?

- the control console which is considered as the brain of the CNC machine

- the table on which the workpiece is clamped

- the column giving the workpiece the required stability

- the tools such as milling, cutting, or turning tools

- the axes allowing the movement of the cutting tools as well as of the workpiece

- the spindle as a rotating mount for the used tool

- the engine for driving the workpiece

- the frame ensures a maximum stability level of all components of the machine

- coolant supply