No.411 Jianlin Road SND, CN-215151 Suzhou

Frau Fiona Luo/罗琪

Tel: +86-512 68419125

Mobile/手机: +86-18013106371

Fax: +86-512-66673556

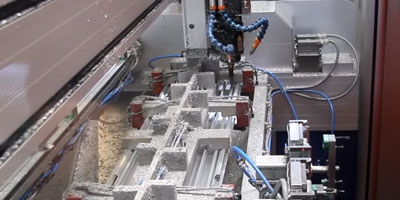

CNC Gantry Milling Machine OverHead - our flexible space-saving option

Gantry CNC Machine, available in four different sizes for different process areas!

Pneumatic sliding door

(version with 4 pneumatic cylinders and safety stop bar, can also be retrofitted to the isel CNC machine series OverHead, EuroMod and FlatCom)

Maximum functionality with minimum space requirements is the motto of the OverHead Gantry M. The basic machine can be optimally configured for many sectors and work areas using a variety of variable equipment features and additional options.

The possible applications of the OverHead Gantry M include measuring, testing and metering applications in addition to machining. The power of the milling motor of up to 2.2 kW and 20,000 rpm and a traverse speed up to 250 mm/sec make it suitable for processing wood and plastic as well as light and non-ferrous metals. The free processing area and its excellent price/performance ratio off er decisive benefits compared to similar products.

The OverHead® Gantry M is available in five different sizes for different process areas from M20 to M50.

Do you require the control cabinet on the right-hand side or would you prefer the control panel to be on the left?

No problem – we will be happy to accommodate your requirements. And of course we will take care of maintenance and support for your OverHead® Gantry M.

Our service technicians can be reached by telephone and can attend to you quickly on-site as needed. In addition, we also off er our in-house isy-CAM 2.8 software and can advise you on your specific application.

Options

- Pneumatic sliding door

4 pneumatic cylinders open and close the parallel sliding door automatically

Polycarbonate panes and safety impact bar (no risk of entrapment) are installed for safe use

The modular design allows retrofitting to the isel CNC machine series OverHead, EuroMod and FlatCom - iSA milling spindles and water-cooled HF milling spindles

- round and linear tool changing stations

- cooling spray device

- cold air cooling Cool-Min

- automatic tool length measurement

- mill breakage control

- electronic handwheel

- pneumatic sliding door

- rotation units

- a maximum of 6 interpolating axes + 6 handling axes

- safety light curtain

- closed and/or light-tight hood for laser applications

- hood attachment with increased portal passage

- workpiece clamping systems (hand lever, vacuum clamping tables, etc.)

- extraction systems

- Lateral loading for integration into production lines

- LED engine room lighting

- RAL colour selection

- PC control panel with free PCI slots (for the use of external PCI hardware)

- interface adjustments

- CAD/CAM software

Ideally suited for:

- gluing and dispensing

- laser applications

- welding

- handling

Features

- completely free table clamping surface

- powerful isel control with maintenance-free servomotors

- reliable LES units with steel ball screws installed as drives

- easy to use thanks to the height-adjustable CNC panel

- network-compatible control PC with WIN 10

- parallel sliding door

- clamping of the workpieces by means of a T-slot plate

- variable portal passages according to the respective customer application

Set up

- Portal: mobil, Table: Fixed

For the processing of :

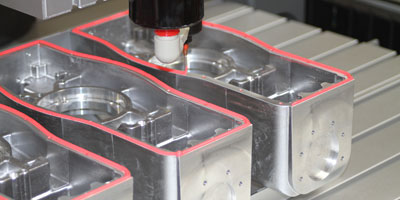

- light and non-ferrous metals

- foam and milled plastics

- ceramics

- plexiglass

- and many more

* without mounted components on the axles!

| OverHead M20 | OverHead M30 | OverHead M40 | OverHead M50 | OverHead M60 | |

| Travel ranges X/Y/Z [mm] | 710 / 610 / 310 | 710 / 910 / 310 | 1210 / 910 / 310 | 1210 / 1410 / 310 | 1510 / 1710 / 310 |

| Z-stroke [mm] * | 310 (optional 410; 510) | ||||

| Z passage [mm] * | 340/390 (optional 440/490; 540/590) | ||||

| Table clamping surface WxD [mm] | 1100 x 1000 | 1100 x 1300 | 1600 x 1300 | 1600 x 1800 | 1750 x 2000 |

| Dimensions WxDxH [mm] | 1440 x 1240 x 2214 | 1440 x 1540 x 2214 | 1940 x 1540 x 2214 | 1940 x 2040 x 2214 | 2290 x 2445 x 2224 |

| with switch approxbinet u. open door | 1728 x 1245 x 2472 | 1691 x 1545 x 2472 | 2192 x 1545 x 2472 | 2228 x 2045 x 2472 | 3153 x 3267 x 2424 |

| Traversing speed X/Y/Z | 15 m/min. | ||||

| Drive motors | maintenance-free EC/AC servo motors | ||||

| Repeatability [mm] | ± 0,02 | ||||

| Drive elements X/Y/Z | Ball screws 16 x 10 / 16 x 10 / 16 x 5 mm, adjusted backlash-free | ||||

| Control | approxN controller iMD with 4 drive controllers, expandable to 12 axes (max. 6 interpolated and 6 handling axes), PC, I/O module, safety circuit with standstill monitoring, power supply 48 V / 1000 W |

||||

| Operation | Control panel iOP-19 Touchscreen with keyboard and touchpad | ||||

| Weight (kg) | approx. 690 | approx. 710 | approx. 750 | approx. 910 | approx. 1150 |

| Software | WinRemote (optional: ProNC, isy-approxM) | ||||

| Connection values | 400 V / 16 A | ||||

| Item no. | 278020 343443* | 278021 343443* | 278022 343443* | 278023 343443* | 278024 343443* |

Technische Änderungen unter Vorbehalt.