- Category

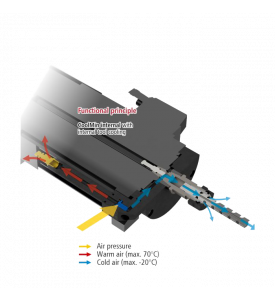

Tool and Material Cooling

-

Minimalmengenkühlsprühgerät mit 1 verstellbaren Düse, inklusive 1l Sprühöl€2,299.10Excl. 19% VATLearn MoreIn stock

Minimalmengenkühlsprühgerät mit 1 verstellbaren Düse, inklusive 1l Sprühöl€2,299.10Excl. 19% VATLearn MoreIn stock

Dry cutting is today the first choice for many machining tasks. Hitherto, materials, tool wear and surface finish have often necessitated cooling with appropriate coolants / greases. This always means moisture. Even minimal moisture spray cooling causes unwanted effects such as the build-up of dirt and the adhesion of swarf to the cutting tool or to the working surface and can lead to the deterioration of the material surface structure, depending on the material being machined.

Our patented cooling method ensures adequate tool and surface cooling and reduces such effects to negligible levels. This keeps the swarf dry and, depending on the material, easy to remove by either blowing or vacuuming. Surfaces are therefore protected and, as a result of direct tool cooling, tool life is significantly increased (also suitable for tools with integrated cooling).