- Category

晶圆传感器 - 附件

Do you have any questions?

-

Wafer Mapping Sensor IMS-MDW1Learn MoreIn stock

Wafer Mapping Sensor IMS-MDW1Learn MoreIn stock -

Wafer Mapping Sensor PD 45Learn MoreIn stock

Wafer Mapping Sensor PD 45Learn MoreIn stock -

Through Beam SensorLearn MoreIn stock

Through Beam SensorLearn MoreIn stock -

Flip Modul IFM-300-3Learn MoreIn stock

Flip Modul IFM-300-3Learn MoreIn stock -

Yaw axisLearn MoreIn stock

Yaw axisLearn MoreIn stock -

Aligment on the flyLearn MoreIn stock

Aligment on the flyLearn MoreIn stock -

End effector changerLearn MoreIn stock

End effector changerLearn MoreIn stock

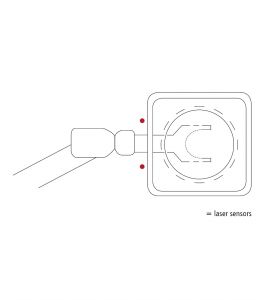

Wafer mapping sensor IMS-MDW1

The wafer mapping sensor which has been specifically designed for the semiconductor industry works using a double triangulation principle and has a measuring distance of 45 mm. The focussing transmitter optics and the innovative dual-segment receiver element ensure that the position of wafers (> 3 inches) is detected precisely regardless of their thickness and coating. The areas of application for this triangulation sensor include processing technology (e.g. wafer painting and exposure machines etc.) in the semiconductor and micro-electronics industry.

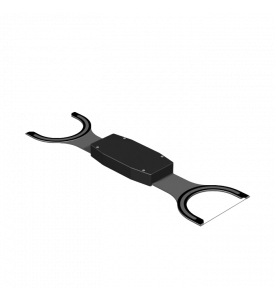

Through-beam sensor

The use of through-beam sensors, e.g. in the tip of a horse shoe end effector, is an alternative to the universally used reflective mapping sensors. The advantages of this method, compared to conventional mapping sensors, are the insensitivity to specially reflective or light-absorbing coatings or materials and its cost effectiveness. However, for engineering reasons it is not possible for all end effectors. Please speak to us about possible other solutions which we can also offer in addition to the standards.

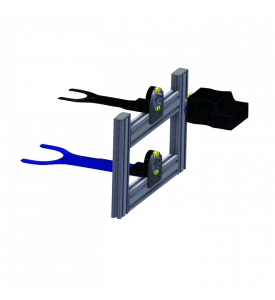

Flip module IFM-300-3

The flip module provides the user with the option of turning wafers and other substrates by a fixed angle without having to set them down. The use of adjustable limit stops, electronic ramps and infinitely variable speeds ensures a high level of precision. Almost all end effectors and an optional mapping sensor can be installed. Use is not possible with all robot models.

Hand-held terminal IHT (standard controller)

The IHT hand-held terminal for the integrated standard controller enables the user to select between the terminal function and the teach function (JOG mode) and programme the robot without a computer. Its compact construction and the spiral cable gives enables the user to move easier around the plant and thus adjust all positions alone.

Teach pendant (advanced controller)

The teach pendant of the advanced controller is the latest development in or product range. It enables the user to move the wafer handler with high precision and safely without the help of another person and to programme or adjust stations. The 6.5" touch display with the innovative GUI allows the user to work intuitively and easily and is also equipped with softkeys which can be used, for instance, to select individual axes and increments. However, most users will learn to appreciate the integrated hand wheel which speeds up the setting up process for stations enormously. Further important features include the "deadman switch" and the maintenance of the safe speed in set-up mode which is required as per the safety regulations for industrial robots. Thus it is ensured that even one person, working alone, can teach in a robot directly in the cell without risk.