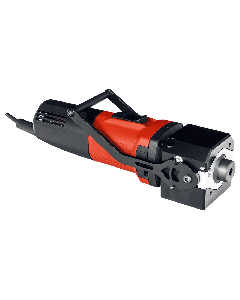

Spindle motors - Milling motors

|

|

CNC router spindle motors from isel Germany, robust, inexpensive and especially maintenance-friendly!

In developing our cnc machine spindle motors, we place a great deal of importance on functionality, quality and optimum pricing. In addition, our cnc machine spindles are particularly easy to maintain and are suitable for isel CNC Machines and CNC Milling Machines.

Series arrangements with minimum spacing can be realized through the slim design and the square cross-section of the housing.

In terms of the electrical construction, our motors have three-phase squirrel cage motors with 2-pole windings, laid out according to DIN EN 60034. The insulating material of the windings is manufactured according to Insulation Class F.

The motors are finely balanced dynamically, so that good running characteristics are attained even at high speeds. They cover a speed range of 3,000 to 30,000 rpm overall.

All spindle motors are completely manufactured in Germany, fulfil the minimum requirements of Protection Class IP54 and are therefore also permitted for the wood dust area I wonder if this should be the “woodpulp industry” or “wood dust areas”.

In our product range, you will find not only the spindle motors themselves, but also all required cables in different lengths and preset, reliable frequency converters for the controller connection.

We are an easy-to-use service in comparison to many of our competitors and possess our own year-round repair service, due to the integration under one roof of our development, production, sales and service departments.

Our product palette is completed by comprehensive accessories, such as dust collectors, minimum quantities - lubrication technology, collet chucks (Swiss quality), SK-collets, tool changers and our unique, patented CoolMin system for optimum and economic mould cooling without residue.