Jürgen Balzer

Phone: +49 (0) 6659 / 981-774

Fax: +49 (0) 6659 / 981-776

juergen.balzer@isel.com

Stefan Koch

Phone: +49 (0) 6672 / 86792-526

Fax: +49 (0) 6672 / 86792-777

stefan.koch@isel.com

Frank Schneider

Sales Manager

Phone: +49 (0) 6659 / 981-489

Fax: +49 (0) 6659 / 981-776

Mobile: 0151/524 279 70

frank.schneider@isel.com

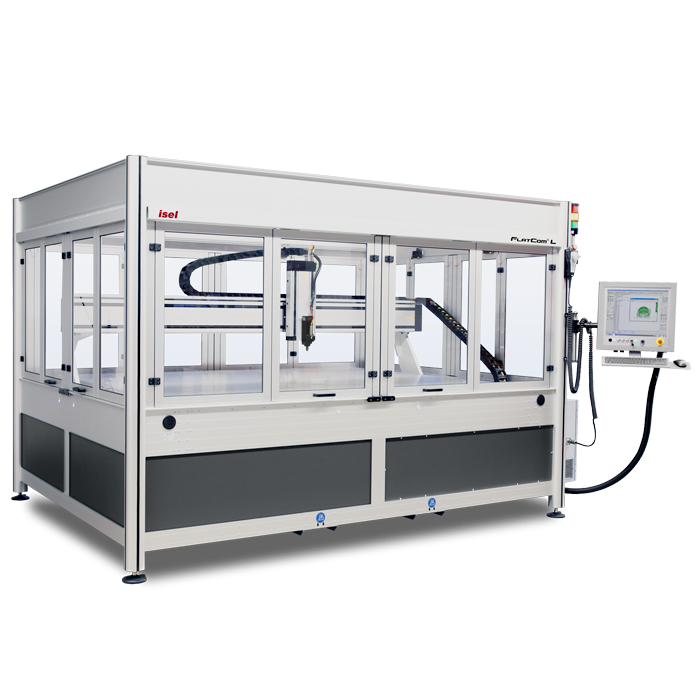

FlatCom® L series with servo motor drive

Pneumatic sliding door (example OverHead)

(version with 4 pneumatic cylinders and safety stop bar, can also be retrofitted to the isel CNC machine series OverHead, EuroMod and FlatCom)

Large machining area, from 1700 up to 2500 mm

The FlatCom L is a robust machine for machining with cutting and non-cutting processes in the wood industry, advertising sector, as well as for various types of assembly work. With traverse paths of 1700 x 2500 mm, it is the largest CNC machine in the comprehensive product range of isel Germany.

With innovative enhancements such as a vacuum table, variable-speed spindle motors, different types of tool changing stations as well as handling systems from our robotics department, you are well-equipped for the future.

Ideally suited for:

- for cutting and non-cutting machining in the wood industry, advertising technology or also for various assembly work (stable machine)

- multi-shift operation

Machining of

- light metals,

- non frrous metals (brass, bronze etc.)

- CFRP

- Ceramic

- plastics

- wood

Benefits

- 5-axis machining

- Large machining area of up to 1700 x 2500 mm

- Gantry drive

- Mobile portal, fixed table

- Removable cover

Set up:

- Portal: fixed, bench: moveable

Options

- Pneumatic sliding door

4 pneumatic cylinders open and close the parallel sliding door automatically

Polycarbonate panes and safety impact bar (no risk of entrapment) are installed for safe use

The modular design allows retrofitting to the isel CNC machine series OverHead, EuroMod and FlatCom - cooling spray device

- Coolmin

- blade tray

- tool length sensor

- spindle motors (up to iSA2200 applicable)

- round changing systems SK 11 and SK 20

- linear changing systems SK 11 and SK 20

- SK11/SK20 automatic tool change stations

- 4th axis with tailstock unit

- 4th + 5th axis as rotary tilting unit

- LED-lighting

- RAL special colour according to customer requirements

- machine handwheel

- safety light curtain

- size adjustment

- openings in the machine table

- further doors

- laser safety glass

- closed hood attachment

- CAD/CAM-Software

- workpiece clamping systems (hand levers, vacuum plates, etc.)

- extraction systems

- rotating units

- cutter breakage control

- customer-specific adaptations

- extension of valve terminals

- I/O distributor

- I/O Coding

- mechanical height sensor

- sealing air kit for milling motors

- various postprocessors CAD/CAM

- interface adaptations for laser devices

- PC control console with free PCI plug-ins (for use by external PCI hardware)

- stainless steel keyboard

- milling and engraving spindles

- vacuum clamping tables

- suction device

- closed or light-proof hood for laser applications

- maximum 6 interpolated axes + 6 handling axes

- portal passage 435mm

- suction device

- version without hood

- maximum 6 interpolated axes + 6 handling axes

- portal gap according to customers request

Attention! The CNC machine FlatCom L150 has no revolving doors.

Subject to change without prior notice.

| L 150 | L 250 | |

| Processing areas X/Y [mm] | 1500 / 1700 | 2500 / 1700 |

| Z lift [mm] | 210 (310; 410 as option) | |

| Z gap [mm] | 270 (370; 470 as option) | |

| Bench clamping area WxD [mm] | 1600 x 2250 | 2600 x 2250 |

| Dimensions WxDxH [mm] with control cabinet | 2241 x 2455 x 2211 | 3488 x 2455 x 2211 |

| with control cabinet & open doors | 2488 x 3280 x 2211 | 4173 x 3778 x 2211 |

| Processing speed X/Y/Z | max. 15 m/min | |

| Drive motors | maintenance-free EC/AC servo motors | |

| Drive elements X/Y/Z | Ball screws, adjusted backlash-free | |

| Controller | CAN controller iMD with 3 drive controllers expandable to 12 axes (max. 6 interpolated & 6 handling axes), PC, I/O module, safety circuit with standstill monitoring, power supply 48 V / 1000 W, PILZ safety technology inside |

|

| Control |

Control panel iOP-19 Touchscreen with keyboard and touchpad | |

| Weight [kg] | ca. 590 | ca. 690 |

| Software | WinRemote (as option: ProNC, isy-CAM) | |

| Connection values | 400 V, 16 A | |

| Part-no. (Z gap=210mm) | 278030 272443* | 278031 272443* |

* without mounted components on the axles!

Als CNC-Bearbeitungszentrum dient eine CNC-Maschine der Serie FlatCom L, die in Kooperation mit dem Kunden zu einer Sonderapplikation modifiziert wurde. Hier werden Strangpressprofile gefräst/bearbeitet, die ihren Einsatz in der Automobilindustrie findet.