Jürgen Balzer

Phone: +49 (0) 6659 / 981-774

Fax: +49 (0) 6659 / 981-776

juergen.balzer@isel.com

Stefan Koch

Phone: +49 (0) 6672 / 86792-744

Fax: +49 (0) 6672 / 86792-777

stefan.koch@isel.com

Frank Schneider

Sales Manager Germany

Phone: +49 (0) 6659 / 981-489

Fax: +49 (0) 6659 / 981-776

Mobile: 0151/524 279 70

frank.schneider@isel.com

iMG 1510 X5 - CNC Milling Machine

5 Axis Simultaneous Milling Machine for Wet and Dry Machining

The metal/granite sandwich construction for the moving axes such as gantry and crosshead can be driven by linear motors. It forms, in conjunction with high-precision linear guides, the

base of the solid steel/granite machine construction. The advantages of natural stone granite in conjunction with high-strength light metal provide maximum rigidity while saving weight.

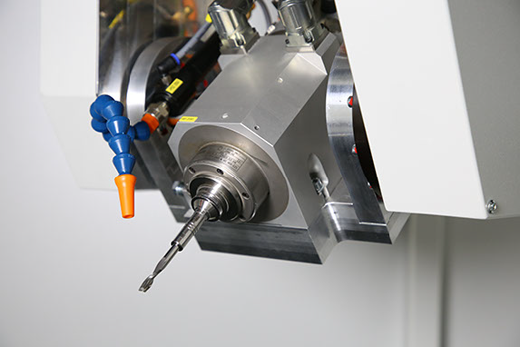

This is the only way to achieve the desired dynamics and high feed rates. High-frequency spindles with 1.5 KW, 2.0 KW or 4.0 KW and 40000 or 50000 rpm with HSK25 mounting are used as milling spindles.

The 10-position tool changer installed outside the working area automatically moves from the protective housing to the milling spindle. With the 4th/5th axis as a fork head design and the integrated high-precision gear drive modules, largely all positions of a complex workpiece can be reached with the milling tool.

The machine is rounded off with new state-of-the-art CNC control functions and an easy-to-use user interface. These allow 5-axis simultaneous machining via RTCP (Rotation Tool Center Point) function. The control and operating components from Heidenhain include a touchscreen monitor and a convenient hand control. Different workpiece clamping systems can be applied to the universal granite table via steel threaded bushings in a 150x150 mm grid, or a T-slot plate can be used.

Features

- Metal/granite sandwich construction

- Rotary swivel cable head (4th And 5th axis)

- High dynamic linear motors in X and Y - axes

- 18-fold tool changer expandable to 36 tools

- Heidenhain® TNC640 high-end control

- Tool measurement by toolsetter or laser

- 3D edge finder

- Handwheel

- Modern control panel

Options

- Water cooling

- Heidenhain LMT TT160 / optional laser measurement

- 3D probe

- Handwheel

- Minimum quantity cooling

- Tool holders

Application areas

For a wide range of applications, we offer different workpiece clamping systems that can be mounted on the universal granite table via steel threaded bushings in a grid of 150x150 mm. alternatively, a T-slot plate can also be used.

The machine is also equipped with state-of-the-art CNC control functions and has a user-friendly interface that enables 5-axis simultaneous machining via RTCP - function (Rotation Tool Center Point). Heidenhain control and operating components include a touchscreen monitor and a convenient handheld control.

Popular materials:

- Precious metals for jewelry manufacturing

- Stainless steel

- hardened steel

- Graphite

- ceramics

- Plastics such as PMMA/composite

- Copper

- Steel

- Titanium

- Special materials

Areas of operation

- Medical technology

- Fine mechanics

- Micromachining

- Molding and prototyping

- Dental technology

- Jewelry industry

The 18-position tool changer, which is installed outside the work¬ing area, automatically moves from its protective housing to the milling spindle.

With the 4th/5th axis in the form of a clevis and the built-in super accurate gear drive modules, you can pretty much reach all positions of a complicated workpiece with your milling tool.

For the milling spindles, we use high-frequency spindles with 1.5 KW, 2.0 KW or 4.0 KW and 40000 or 50000 rpm with HSK25 mounting.

| iMG1010X5 | iMG1510X5 | iMG2010X5 | iMG2015X5 | |

| Travel ranges X/Y/Z/A/C [mm]* | 1000/1000/350 | 1500/1000/350 | 2000/1000/350 | 2000/1500/350 |

| Rotating/swivel clevis A/C | ±115°/±250° | |||

| Travel speeds X/Y/Z | 8m/min. Spindle drive, 30m/min. linear motors | |||

| Z-diffuser | 450 mm | |||

| Drive motors | AC servo motors with precision ball screws or linear motors | |||

| Milling spindles | High frequency spindle up to 6 kW / 45,000 rpm | |||

| Resolution measuring system | 0.001 mm | |||

| Dimensions WxDxH [mm] | 2300 x 1950 x 2000 | 2800 x 1950 x 2200 | 3300 x 1950 x 2200 | 2800 x 2450 x 2200 |

| Control | Heidenhain® | |||

| Software | Heidenhain® | |||

| Operation | Heidenhain® operating unit with touchscreen, operating buttons, keyboard and handwheel | |||

| Item number | on request | 282015 SDU 8300 | on request | on request |