Jürgen Balzer

Phone: +49 (0) 6659 / 981-774

Fax: +49 (0) 6659 / 981-776

juergen.balzer@isel.com

Stefan Koch

Phone: +49 (0) 6672 / 86792-744

Fax: +49 (0) 6672 / 86792-777

stefan.koch@isel.com

Frank Schneider

Sales Manager Germany

Phone: +49 (0) 6659 / 981-489

Fax: +49 (0) 6659 / 981-776

Mobile: 0151/524 279 70

frank.schneider@isel.com

FlatCom® Series XL (GFV/GFY) | The allrounder

Do you mainly want to machine non-ferrous metals such as aluminum, brass and bronze? Do you need travels of more than 2,000 mm? In this case, our allrounder will come into play. The traversing unit is mounted on the table surface and therefore has a high degree of stability, thus providing a connection to the stiffened machine frame. The machine remains low-vibration even at high speeds.

Don't just take our word for it - see for yourself!

Features

- various portal passages with an extended Z-axis

- powerful isel control with maintenance-free servomotors

- reliable LES units with steel ball screws installed as drives

- easy to use thanks to the height-adjustable CNC panel

- network-compatible control PC with WINDOWS

- sliding/folding door

- clamping of the workpieces by means of a T-slot plate

Ideally suited for:

- automotive suppliers

- model and mold making

- orthopaedic technology

- measurement and testing procedures

- dispensing applications

FlatCom XL - The all-in-one solution

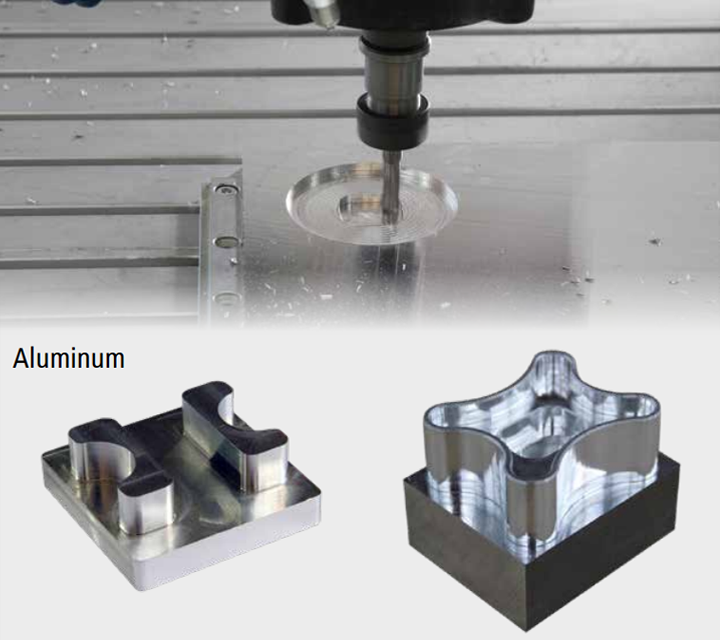

Popular materials:

- aluminum

- brass

- wood

- plexiglass

- foam and milled plastics

- wood

- and many more

Benefits:

- 5-axis machining

- Windows-based software

- Gantry drive

- Mobile portal, fixed table

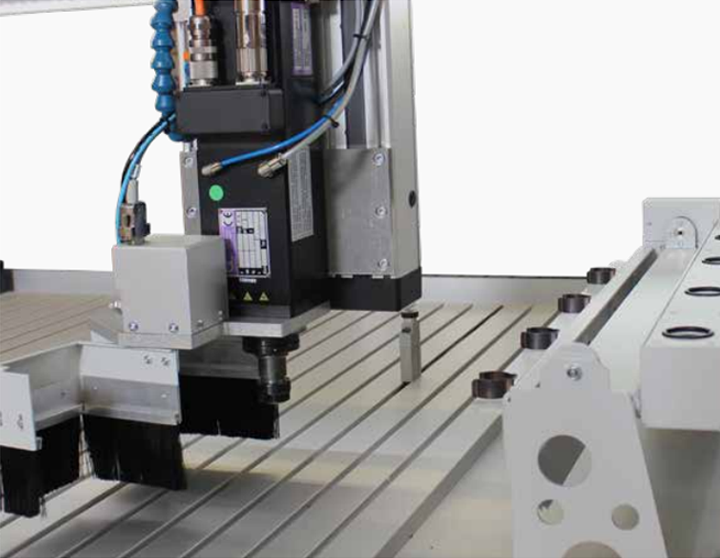

Option: Automatic tool changer with suction device

Options:

- iSA milling spindles and water-cooled HF milling spindles

- round and linear tool changing stations

- cooling spray device

- cold air cooling cool-min

- automatic tool length measurement

- mill breakage control

- electronic handwheel

- pneumatic sliding door

- rotation units

- a maximum of 6 interpolating axes + 6 handling axes

- safety light curtain

- closed and/or light-tight hood for laser applications

- hood attachment with increased portal passage

- workpiece clamping systems (hand lever, vacuum clamping tables, etc.)

- extraction systems

- LED engine room lighting

- RAL colour selection

- PC control panel with free PCI slots (for the use of external PCI hardware)

- interface adjustments

- CAD/CAM software

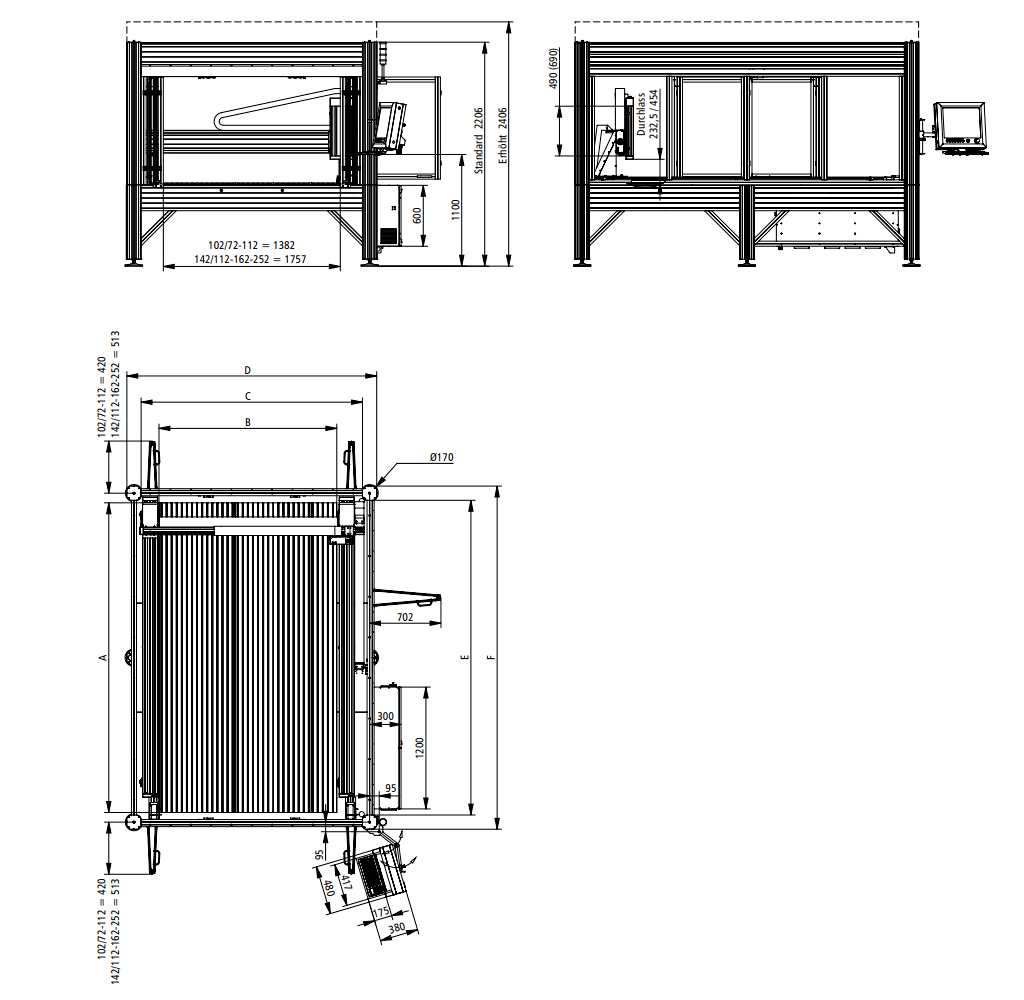

Set up:

- Portal: fixed, bench: moveable

| FlatCom XL | 102/72 | 102/112 | 142/112 | 142/162 | 142/252 |

| Processing areas X/Y [mm] | 1125 / 720 | 1125 / 1100 | 1500 / 1100 | 1500 / 1600 | 1500 / 2500 |

| Z stroke [mm]* | 210 (optional: 410, each without processing unit) | ||||

| Z passage [mm]* | 230 (optional 450, each without processing unit) | ||||

| Table clamping area WxD [mm] | 1375 x 1300 | 1375 x 1700 | 1750 x 1700 | 1750 x 2200 | 1500 x 3100 |

| Dimensions WxDxH [mm] | 2114 x 1614 x 2206 | 2114 x 2014 x 2206 | 2489 x 2014 x 2206 | 2489 x 2514 x 2206 2 | 2489 x 3410 x 2206 |

| Equipped with control cabinet & open doors | 2338 x 1949 x 2206 | 2338 x 2684 x 2206 | 2713 x 2871 x 2206 | 2713 x 3371 x 2206 | 3106 x 4267 x 2206 |

| Travel speed X/Y/Z | max. 15 m/min. | ||||

| Drive motors | Maintenance-free EC/AC servomotors | ||||

| Drive elements X/Y/Z | Ball screw drive, set without clearance | ||||

| Controll | CAN controller iMD equipped with 3 drive controllers which are expandable to 12 axes (max. 6 interpolated & 6 handling axes), PC, I/O module, safety circuit equipped with standstill monitoring, power supply 48 V / 1000 W |

||||

| Operation | Control panel iOP-19 touchscreen equipped with keyboard and touchpad | ||||

| Software | Windows, WinRemote (optional: ProNC, isy CAD-CAM) | ||||

| Weight (kg) | approx. 680 | approx. 730 | approx. 840 | approx. 930 | approx. 1180 |

| Electrical specifications | 400V, 16A | ||||

| Part-No. (Z stroke: 210 mm) | 278040 232443* | 278041 232443* | 278042 232443* | 278043 232443* | 278044 232443* |

*without installed components on the axes

| FlatCom® XL | 102/72 | 102/112 | 142/112 | 142/16 | 142/252 |

| A | 1300 | 1700 | 1700 | 2200 | 3050 |

| B | 1375 | 1375 | 1750 | 1750 | 1750 |

| C | 1804 | 1804 | 2179 | 2179 | 2179 |

| D | 2084 | 2084 | 2459 | 2459 | 2459 |

| E | 1304 | 1704 | 1704 | 2204 | 3100 |

| F | 1584 | 1984 | 1984 | 2484 | 3380 |