Do you have any questions?

Your contact for CNC milling machines & CNC special machines

Jürgen Balzer

Phone: +49 (0) 6659 / 981-774

Fax: +49 (0) 6659 / 981-776

juergen.balzer@isel.com

Stefan Koch

Phone: +49 (0) 6672 / 86792-744

Fax: +49 (0) 6672 / 86792-777

stefan.koch@isel.com

Frank Schneider

Sales Manager Germany

Phone: +49 (0) 6659 / 981-489

Fax: +49 (0) 6659 / 981-776

Mobile: 0151/524 279 70

frank.schneider@isel.com

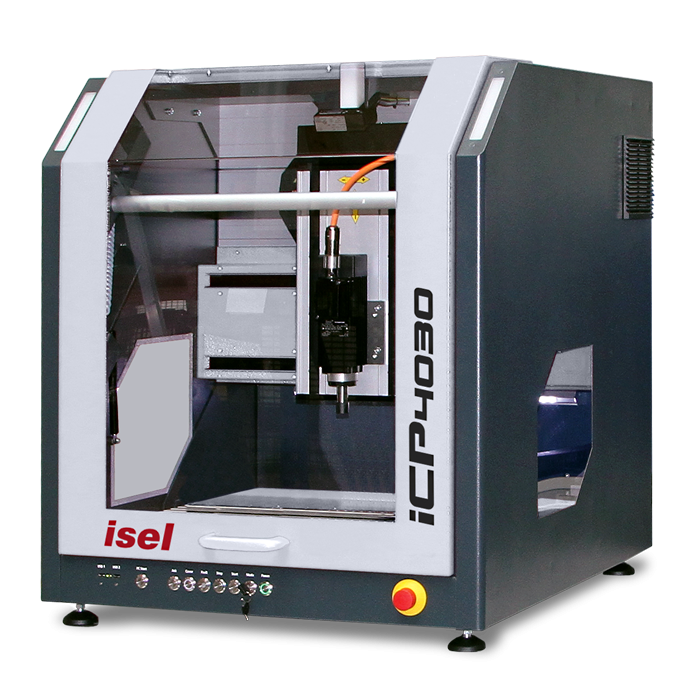

Series iCP - with stepper motor drives - Entry-level model

The low cost CNC-Milling Machine for CNC milling or for other applications!

General

CNC machines in the ICP series have been developed from the proven CPM series. By introducing a sliding door, the machines can now be operated in a sitting position which, inter alia, leads to shorter cycle times when opening the hood. The chassis is completely bolted instead of being welded like its predecessors.

This produces higher precision when building the machine and makes servicing easier. In addition, it was possible to optimise the resonance and vibration behaviour and therefore lower noise build-up has been achieved.

This produces higher precision when building the machine and makes servicing easier. In addition, it was possible to optimise the resonance and vibration behaviour and therefore lower noise build-up has been achieved.

- X = 400mm

- Y = 300 mm

- Z-Axis = 140 mm

- Z-Opening = 200 mm

| ICP 4030 | ||

| Traverse path X/Y/Z [mm] | 400 x 300 x 140 | |

| Clamping table surface W × D [mm] | 700 x 375 | |

| Throughput [mm] | 200 | |

| Dimensions W × D × H [mm] | 769 x 836 x 901 | |

| Guides | Linear units with precision steel shafts and recirculating ball slots, clearance free adjustable |

|

| Process speed X/Y/Z [mm/s] | 100 (for Ball screw drives 16x10) | |

| 60 (for Ball screw drives 16x4) | ||

| Repeatability [mm/s] | ± 0,02 | |

| Drive motors | Stepper motors | |

| Drive elements X/Y/Z | Ball screw drives 16 x 10 / 16 x 10 / 16 x 10 mm Clearance free adjustable (optional: 16 x 4 mm in X/Y/Z) |

|

| Controller | iMC-P step controller with 4 final stages 48V/4.2A, integrated control computer, and 500W power supply unit with processor board |

|

| Operation | Function keys and emergency shutdown | |

| Software | WinRemote (optional: ProNC, isy CAM 2.8) | |

| Weight kg | appr. 150 | |

| Part-No.: | 280270 0001* | |

| * The deliverables include an accompanying pack with mechanical accessories (inter alia Hand lever clamping device, stop rails Triangle wrench, open jaw wrench, hook wrench, Allen key, one 6-socket bench extension, connection lead, power lead) | ||

| Part No. | |

| 680670 9300 | machine stand, RAL 7016/3003 |

| 442107 | monitor support - WLB511, VESA 100 x 100, wall mounting / gas spring |

| 442057 | 23.6" LED-monitor |

| 370321 2003 | metal industrial keyboard with touchpad and 105 Keys, USB-interface, IP68 |

| 280220 9012 | Cooling/spray device for ICP 4030 |

| 280120 9010 | Length measuring button for ICP 4030 |

| 280110 9004 | Workspace lighting for ICP 4030 |

| 420003 0500 | Milling motor UFM 500, 500 W, 11,000...25,000 r.p.m. |

| 280110 9001 | Suction device for UFM 500 |

| Z13-337070 | isy-CAM 2.8 Software |

| Z11-333500 | ProNC Software |

| 310704 1611 | iSA 500 spindle motor up to 30,000 rpm, 500 W, with frequency converter, ER 11 clamping ring and motor lead |

| 280210 9001 | Suction device for iSA 500 / 750 |

| 280000 0046 | Fixing plate for main spindle drive iSA 500 / 750 |

| 290055 | Vice 1 (W 130 x H 45 x L 152 mm) |

| 290056 | Vice 2 (W 180 x H 75 x L 215 mm) |

We found other products you might like!