Jürgen Balzer

Phone: +49 (0) 6659 / 981-774

Fax: +49 (0) 6659 / 981-776

juergen.balzer@isel.com

Stefan Koch

Phone: +49 (0) 6672 / 86792-744

Fax: +49 (0) 6672 / 86792-777

stefan.koch@isel.com

Frank Schneider

Sales Manager Germany

Phone: +49 (0) 6659 / 981-489

Fax: +49 (0) 6659 / 981-776

Mobile: 0151/524 279 70

frank.schneider@isel.com

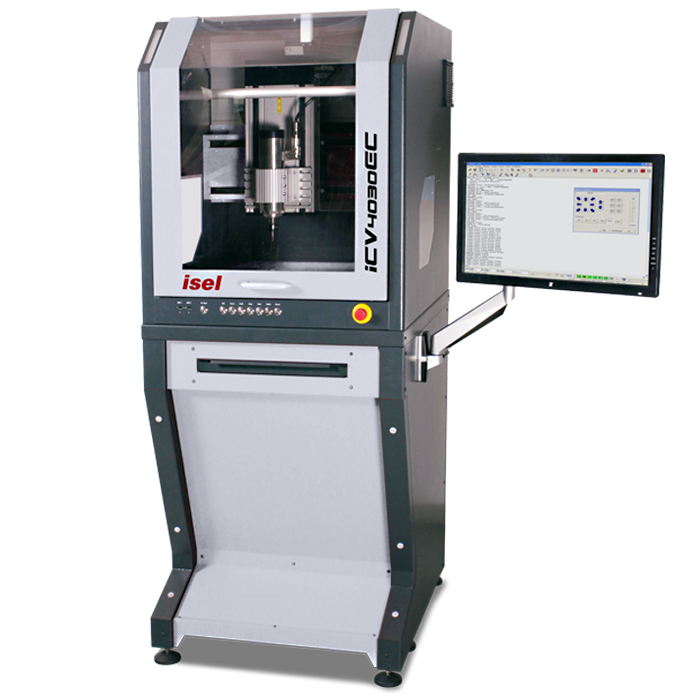

Series iCV CNC Milling Machine with EC Servo Motor Drive

Ready-to-use cnc router with small footprint

Our ready-to-use cnc desktop milling machine iCV 4030 has been proving itself in practice for years and will be presented at the beginning of this year in a completely new design. The newly designed machine door with improved hood opening enables a greater range of travel in the Z axis, and thus a higher throughput. The redesigned machine cover and the resulting larger passage opening now allow for the easy integration of a 4th axis.

Maintenance-free EC servomotors are used as drives, the reliable linear unit LES 5 is used in the X axis. Furthermore, the universal control PC iPC 25 is installed. Central lubrication makes the machine as a whole more maintenance-friendly. Additional signal lights were also integrated.

With a base of only 770 x 836 mm, the machine can be easily operated while sitting in front of it. An isel workbench made of anodized aluminum profiles is the obvious choice as a "base".

The economically priced CNC machine in modular chassis design, offers displacement ranges of 400 x 300 x 140 mm.

A controller including control computer with WINDOWS® operating system and safety features are built in at the rear. An external monitor and keyboard are required. All mechanical and electronic components are bolted together.

All linear axes in the machine are of the isel range and run on precision ground steel shafts with patented linear ball bearings. Linear drives of the ball type with zero backlash are used as drives on the spindle pitch adapted to the application.

The machine table, made of surface-milled precision T-slot profiles, provides optimum clamping capabilities for most different workpiece holders and fixtures.

The four-axis control unit, integrated into the machine, comprehends all electronic modules of the CNC controller, a remote maintenance module provides user-friendly fault analysis as a special service.

Various machining units, clamping systems, measuring fixtures and accessories extend the basis machine to a complete system for most various applications and branches.

Design, production, sales and service of the CNC machines is provided by isel in Germany, authorised partners take care of sales and service abroad.

Base CNC-Milling machine for further applications. (With the appropriate accessories)

isel safty performance - functional safety

Since October 1st 2019, all isel CNC machines have "yellow safety technology" from PILZ "inside".

We are therefore prepared for all future relevant safety requirements and offer you maximum flexibility and peace of mind for your application.

Behind all this is a SIL and PL certification, which our isel customers can also continue to use for their applications.

We have gained valuable experience for the hardware and software from our numerous special machine projects over the past years, which we are incorporating here as a new standard.

You can also use this added value for your application. In future rely on the "yellow technology" from the market leader PILZ!

Suitable for:

- Milling

- Drilling

- Measuring

- Cutting

- Dispensing

- Glueing

- Casting

- Burring

- Polishing

- Testing

- Scanning

- Scaling

- Printing

- Placing

- Mounting

- Screwing

- Etc.

| iCV 4030 | |

| Processing areas X/Y/Z [mm] | 400 / 300 / 140 |

| Bench clamping area WxD [mm] | 700 x 375 |

| Gap [mm] | 200 |

| Dimensions WxDxH [mm] | 769 / 836 / 901 |

| Drive motors | Servo motors |

| Guides X/Y/Z | Linear Units with precision steel shafts and ball recirculation carriage, play-free adjustable |

| Processing speed X/Y/Z [mm/s] | |

| 200 | |

| Repeat accuracy (mm) | 0,02 |

| Drive elements X/Y/Z |

Kogelomloopspindels16x10 / 16x10 / 16x5 mm, spelingsvrij verstelbaar |

| Controller |

CAN-Controller iMC met 3 aandrijvingsbesturingsmodules, geïntegreerde besturingscomputer, |

| Operation | Bediening Functietoetsen en noodstop |

| Software | WinRemote (optioneel: ProNC, CAD/CAM isy 2.8) |

| Weight (kg) | ca. 120 |

| Load values | 230 V / 16 A |

| Deel-no.. | 2802261 0001 |

| Part. No. | |

| 310707 1631 | Spindle motor iSA 750S with CoolMin, frequency converter |

| 310709 3612 | Spindle motor iSA 900W with frequency converter |

| 310712 3612 | Spindle motor iSA 1200W with frequency converter |

| 239171 0001 | Collets ER 16 for iSA 750, 10-piece, Ø 1-10 mm |

| 239011 0053 | Tool changing station 5-fold linear changer, for SK 11 tool holders |

| 239111 0001 | Tool holder SK 11 for collets ER 11 |

| 280120 9010 | Length measuring sensor |

| 239012 0000 | Dust extraction for ISA 500/750, opening manually |

| 239012 0004 | Dust extraction for ISA 900, opening pneumatically |

| 269100 0030 | Tailstock unit RE-XS for rotary axis RDH-XS |

| 266000 0200 | Rotation unit RDH-XS, HD transmission U = 1: 101, full-wave design, servo drive |

| 269060 4065 | Three-jaw chuck |

| 216601 0017 | Vacuum clamping plates VakuFit L, 210 x 150 mm, with holes System |

| 290014 | Clamping elements set mechanically |

| Z13-337070 | isy-CAM 2.8 |

| Z11-333500 | ProNC Software |