Jürgen Balzer

Phone: +49 (0) 6659 / 981-774

Fax: +49 (0) 6659 / 981-776

juergen.balzer@isel.com

Stefan Koch

Phone: +49 (0) 6672 / 86792-526

Fax: +49 (0) 6672 / 86792-777

stefan.koch@isel.com

Frank Schneider

Sales Manager

Phone: +49 (0) 6659 / 981-489

Fax: +49 (0) 6659 / 981-776

Mobile: 0151/524 279 70

frank.schneider@isel.com

Series iMG 1010 for micromachining

Small CNC Machine

The iMG 1010 offers a compact solution for machining workpieces up to 100x100x100 mm. The machine enables a wide range of materials such as aluminum, CoCr or titanium to be machined precisely. The arrangement of the axes enables almost all positions on the workpiece to be reached without the need for reloading. The special mounting of the Y-axis is to be emphasized, which guarantees high stability as well as enormous vibration damping due to its installation position. The selection of workpiece clamping devices and holders in combination with the zero-point clamping system makes the machine a versatile machining center. The design allows wet/dry machining without time-consuming changeover. The basic design allows the machine to be extended by an optional handling system, which can enter the machine room from the right, left or from above. This allows workpieces to be changed automatically.

The zero-point clamping system serves as an interface and ensures the exact and repeatable positioning of the workpiece. By means of software interfaces, the system can be integrated into network-controlled automated manufacturing processes. The maintenance-friendly design and the durable direct spindle drives save service costs and time and offer a reliable machining system. During development, care was taken to ensure that all elements are easily accessible and yet protected from external influences to guarantee a long service life. A wide range of optional extensions are available for the system. For example, a practical base frame is available for storing tools, material or the extraction system.

Precision parts for:

- medical technology

- Precision Mechanics

- Micromachining

- Mould and prototype construction

- Dental Technology

- Jewelry Industry

Features

- 5-axis operation as standard

- 15-fold tool changer

- low vibration

- high accuracy through precision guides

- large operating panel with 24" touch operation

Fields of application

- The machine can be used flexibly for a wide variety of materials.

- Metals and plastics can be processed wet and dry without changeover.

- The zero-point clamping system facilitates the handling of the workpieces.

POPULAR MATERIALS:

- Steel

- Titanium

- CoCr

- Aluminum / light metals

Options

- Machine base

- automatic placement system

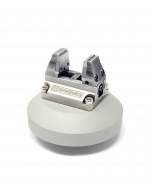

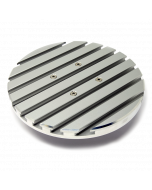

- various clamping devices

- 3D measuring probes

| Travel ranges X/Y/Z [mm]* | 110 (215 including tool changer) x 110 x 110 |

| Turn-swivel unit A/B | A = endless B = 130° (-30° + 100°) |

| Workpiece dimensions [mm] | Ø 100 x L 100 |

| Dimensions WxDxH [mm] | 730 x 815 x 1045 |

| Drive motors |

AC-Servo 200 Watt with absolute encoders |

| Drive elements X/Y/Z | 16 mm ball screw backlash-free |

| Tool changer | 15-fold tool changer with length measuring probe |

| Milling spindles | 1 kW 60,000 rpm. |

| compressed air supply | 6-8 bar |

| Coolant tank | 5 liters |

| Operation | Touchscreen Display |

| Weight [Kg] | approx. 310 |

| Software | WIN 10 / CNC Workbench / remoteNC |

| Connected loads | 110V/ 240V 16A |

| Item No. | 283004 0001 |

*without mounted components on the axles.