Steffan Gärth

Phone: +49 (0) 6659 / 981-773

Fax: +49 (0) 6659 / 981-776

steffan.gaerth@isel.com

Katja Henkel

Phone: +49 (0) 6659 / 981-744

Fax: +49 (0) 6659 / 981-776

katja.henkel@isel.com

More cost-effectiveness thanks to durable modular drive elements

Plug-in, flexible & customized linear units- Bespoke CNC systems

- Maximum manufacturing depth

- Free samples

- Easy to use

- Can be upgraded later

Three out of 1000 satisfied Customers:

Daimler AG

Linear units and multi-axis systems for automation

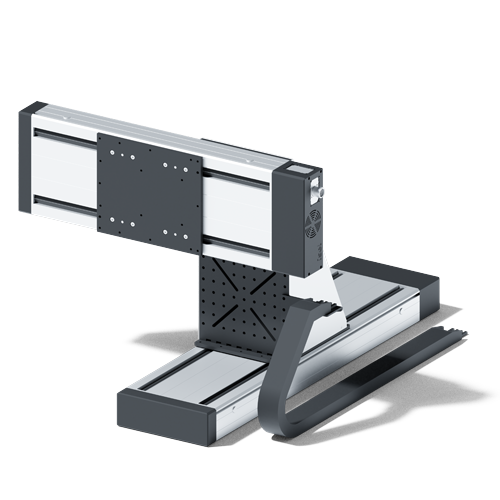

Single Axis Systems

Linear units with spindle drive

Plug-in modules for light machine construction, handling technology and factory automation, manufacturing according to customer specifications

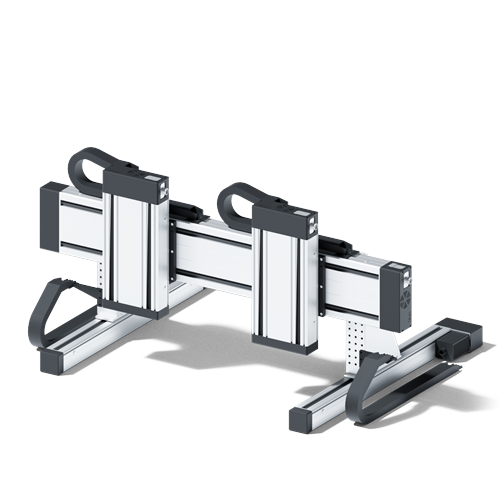

Linear units with belt drive

Fast and accurate positioning and transport of medium-sized work-pieces in assembly automation, handling and machine handling

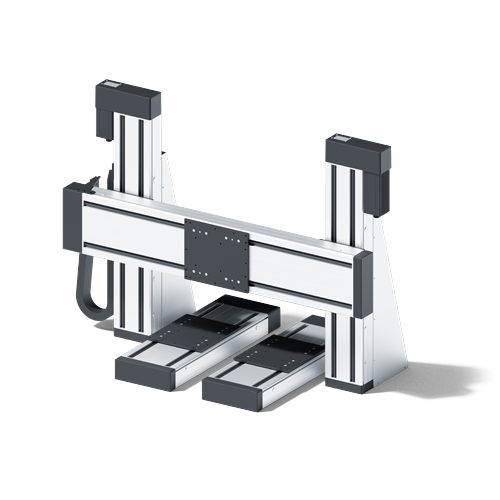

Two Axis Systems

Cross table/Linear table

Multi-axis Systems

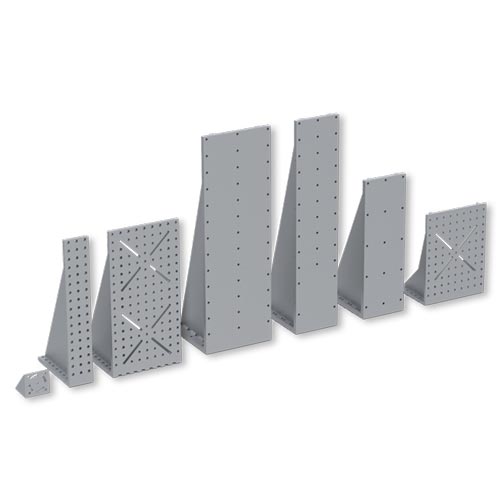

Flexible technology for all requirements

Linear units are now used in almost all areas of manufacturing and mechanical engineering: The more flexible the drive, the better. Linear technology from isel is based on years of experience and many specific customer requirements, which have been incorporated into the further development of our linear units. As a result, we are now able to offer the right linear solution for every application. Even special motor connections are available upon customer request. Please contact us!

Any other questions? We would be delighted to give you more help!

Linear systems play an important role in the productivity and machine throughput of a company. Our employees are the right contact persons for all issues concerning linear units and would be delighted to help you find the best linear solution for your company.